Applications

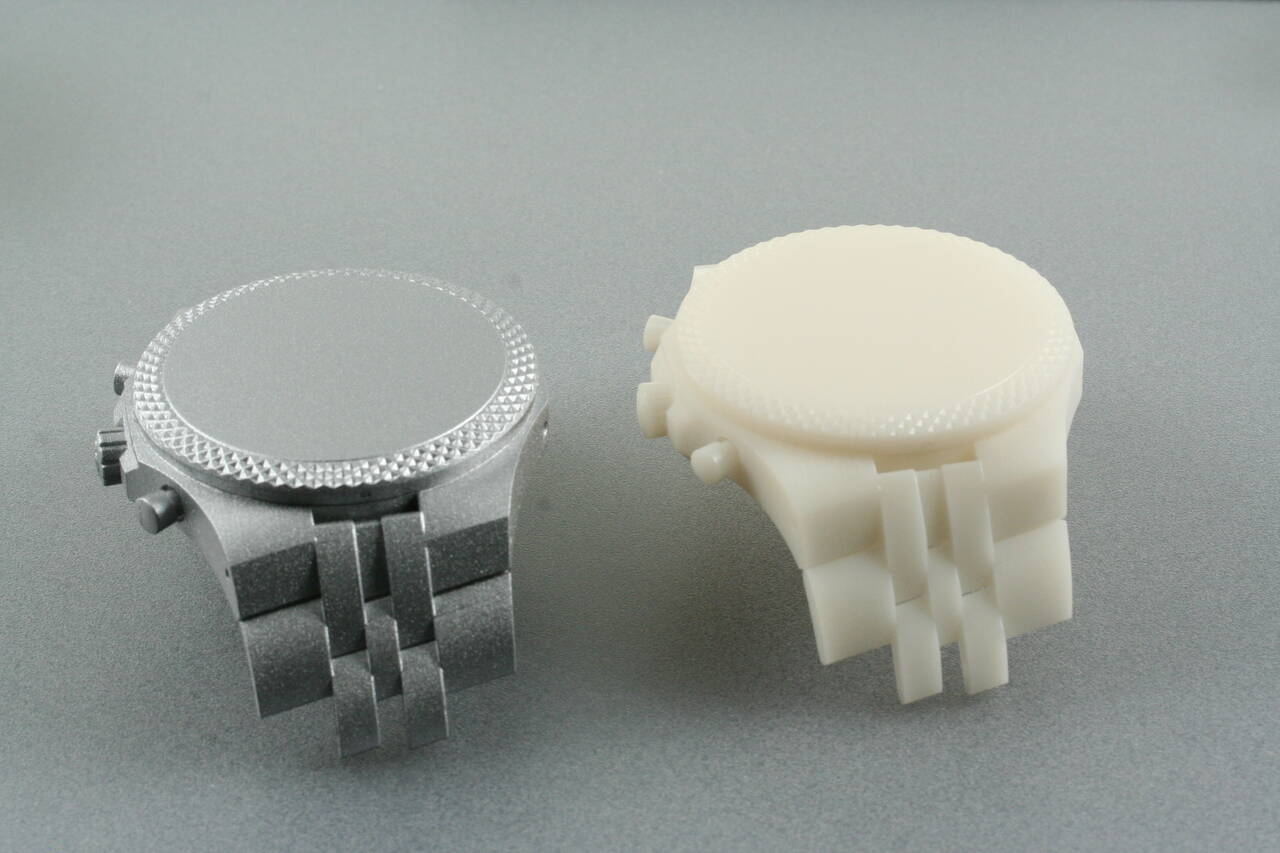

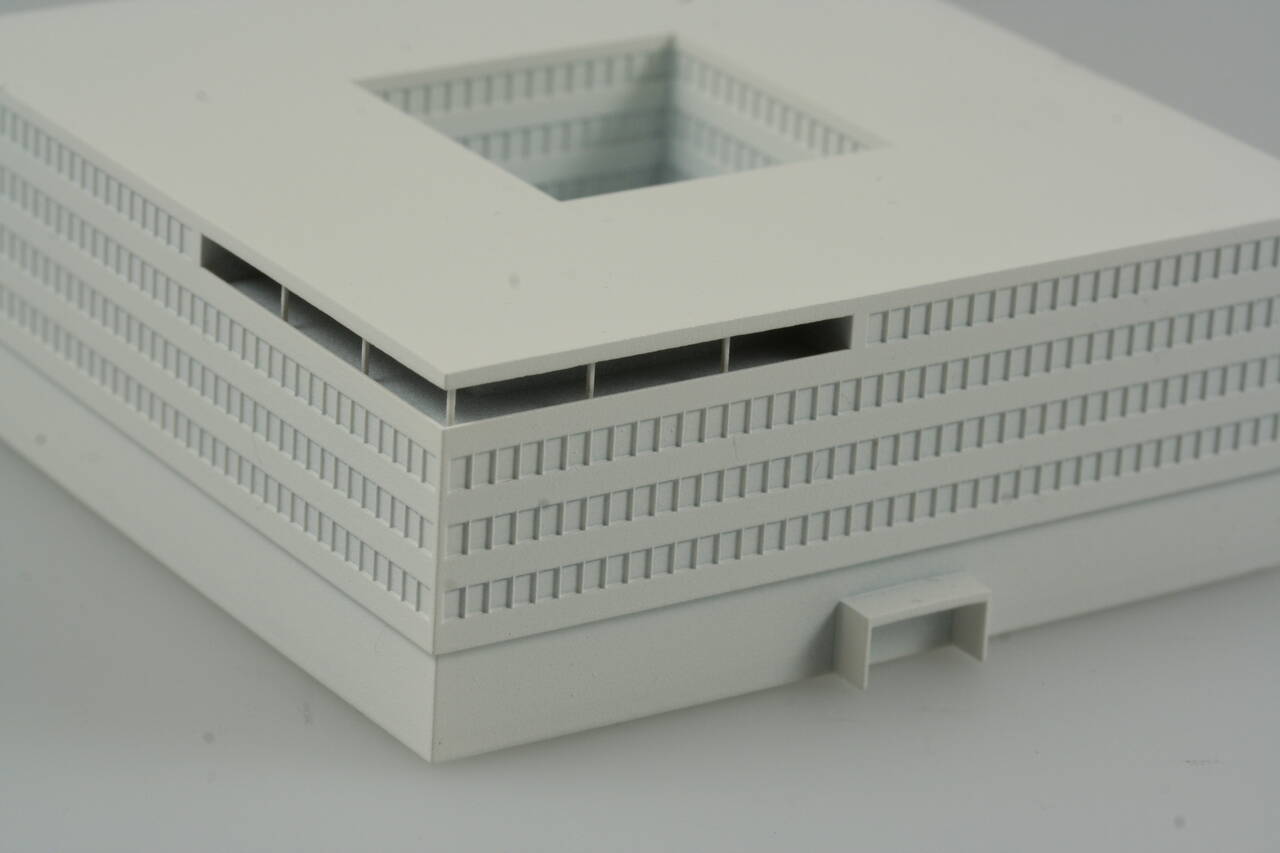

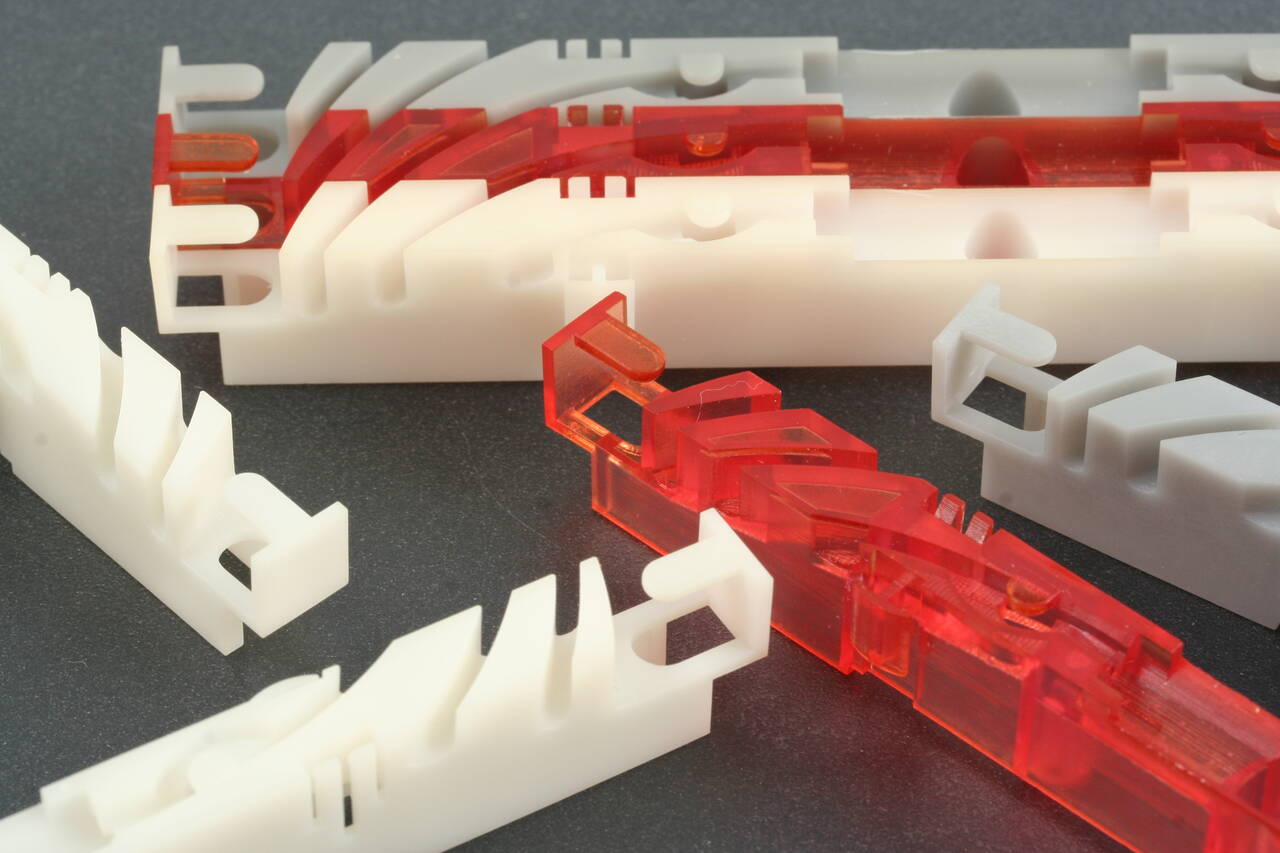

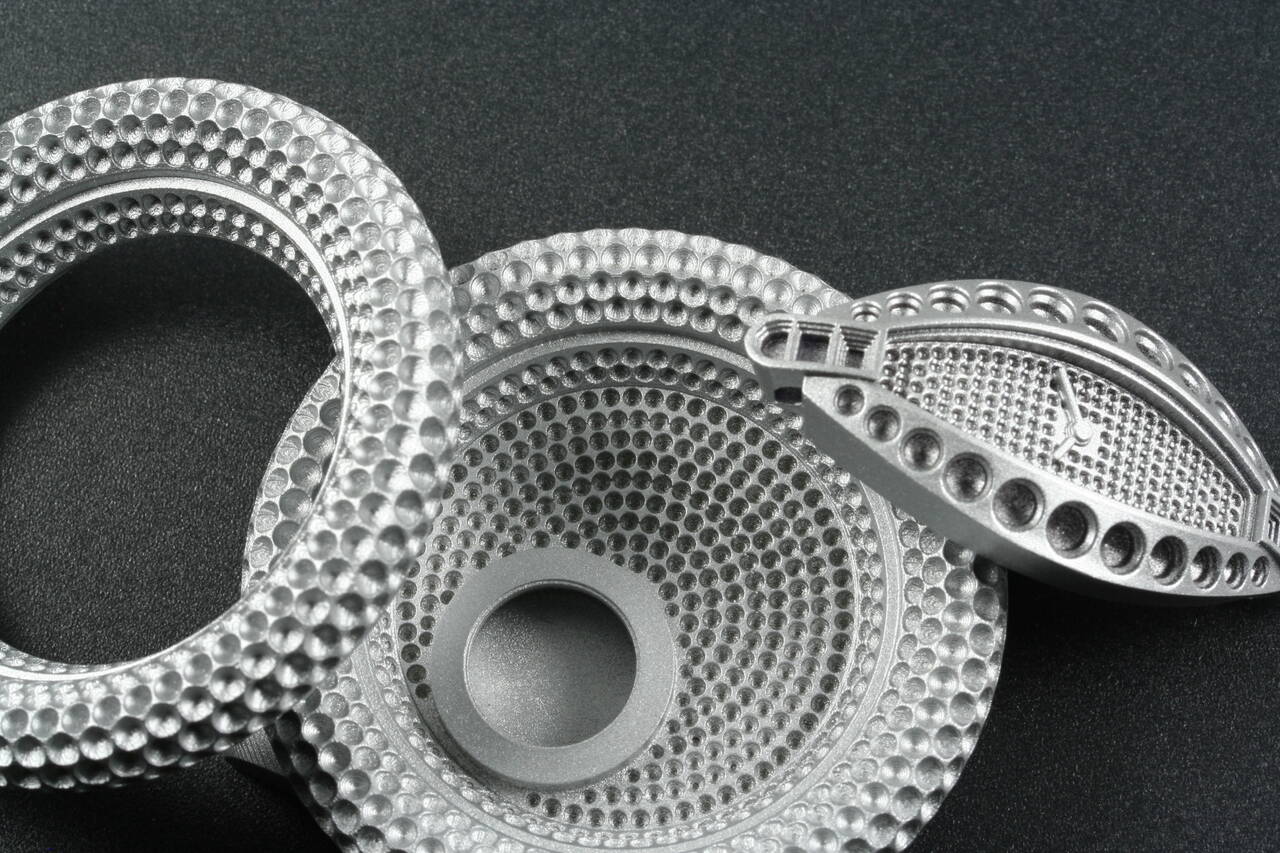

Stereolithography prototypes are used for the verification and optimization of a design, for initial functional testing and for presentations and marketing needs. Thanks to a high precision of 0.1% and the excellent surface quality, these models are suitable as master patterns for various casting processes such as vacuum casting, rapid tooling or metal casting.

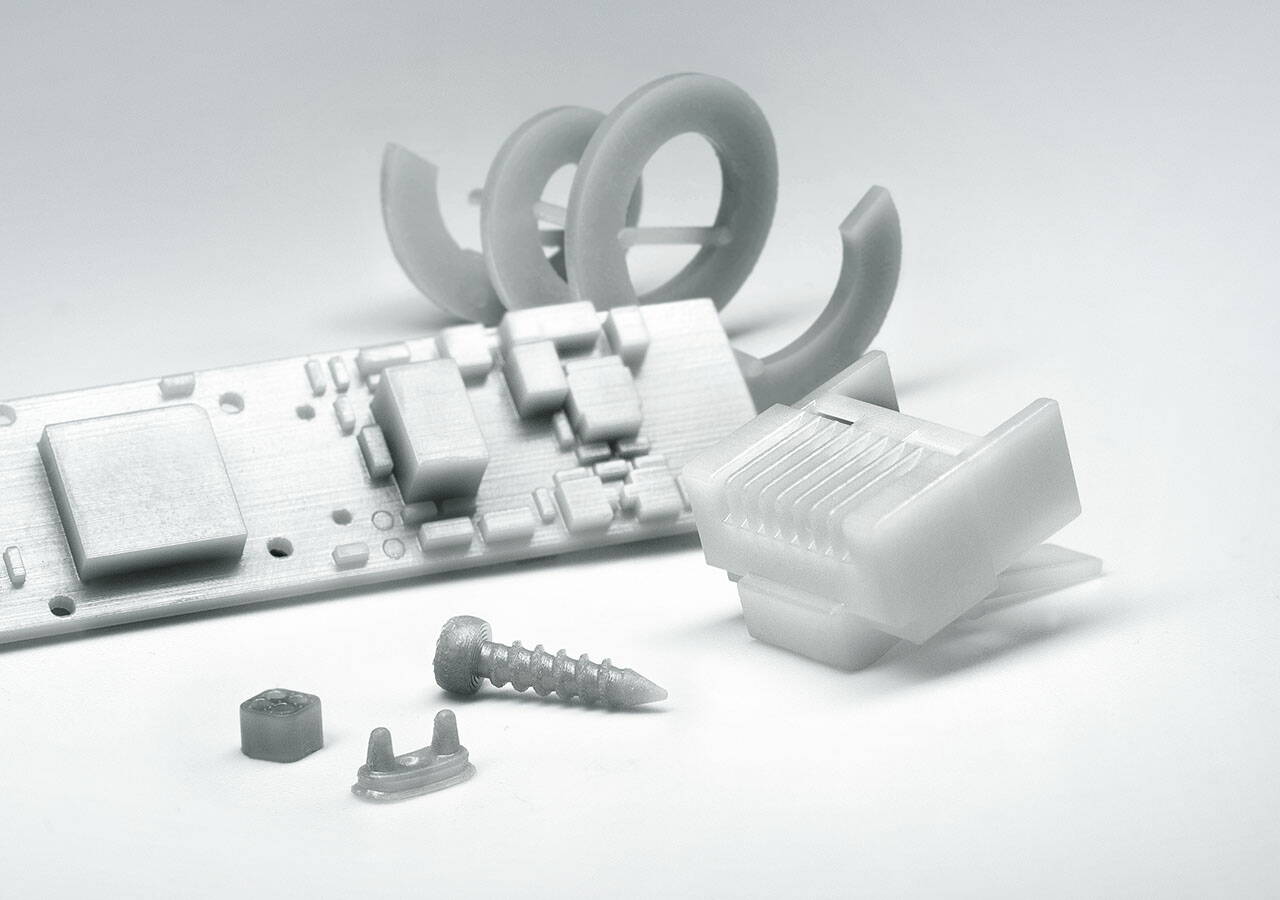

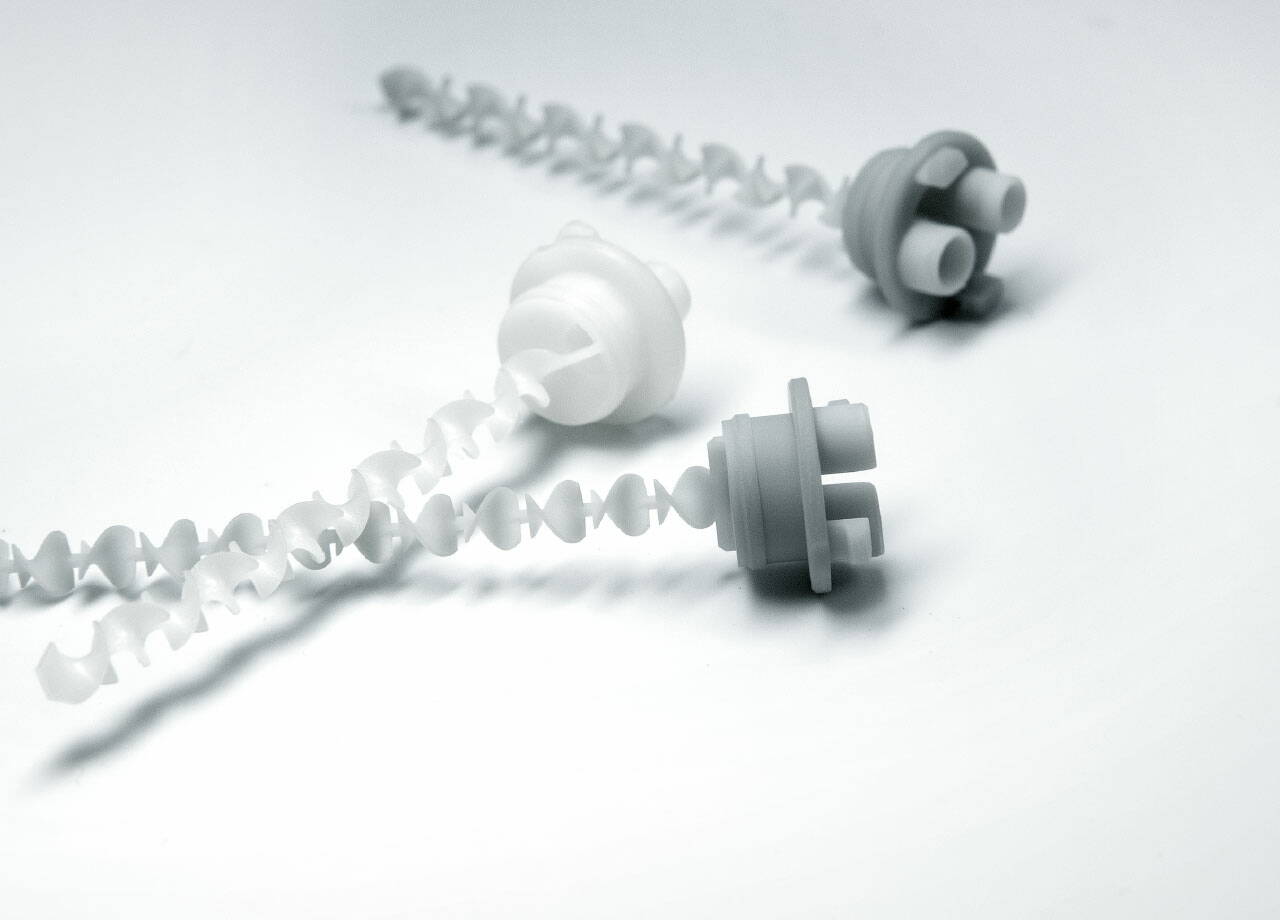

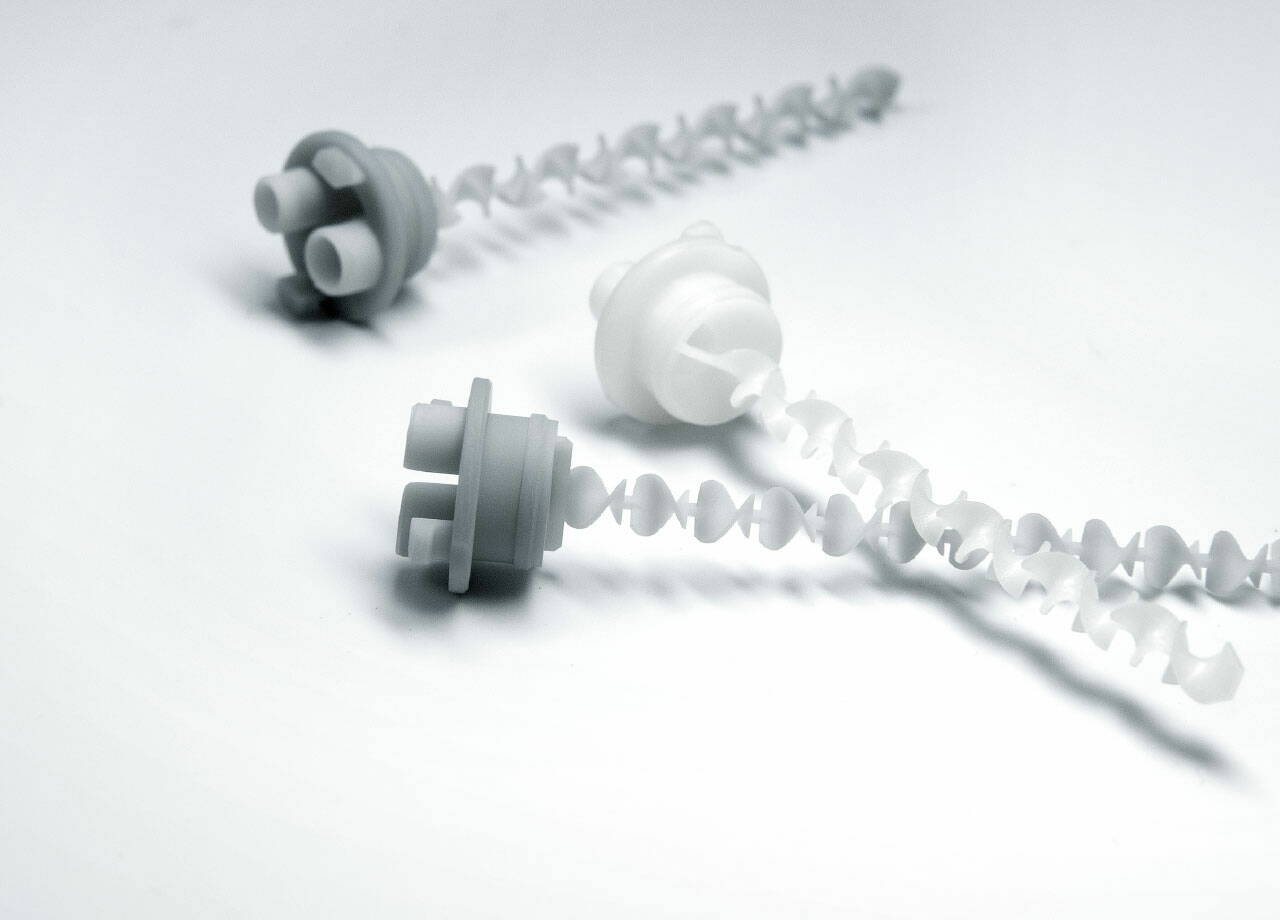

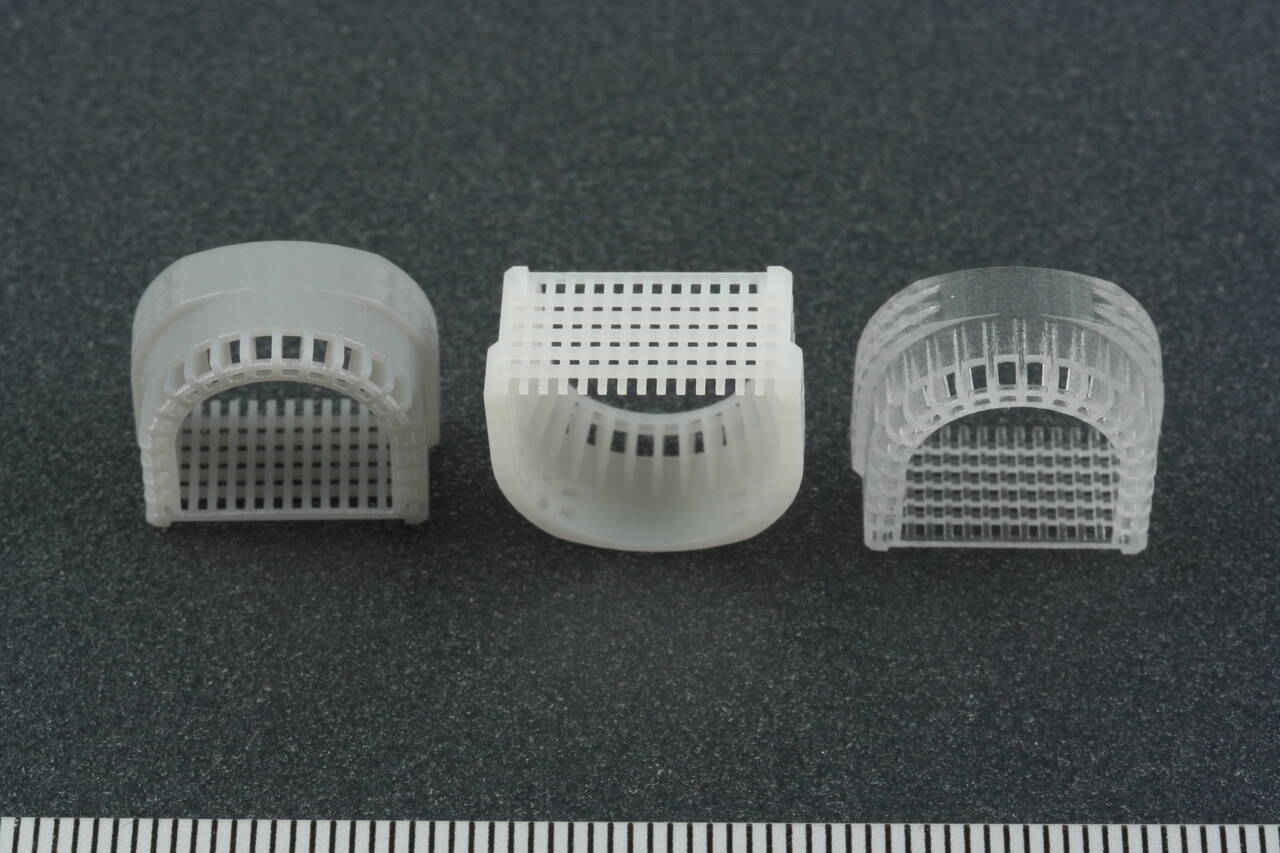

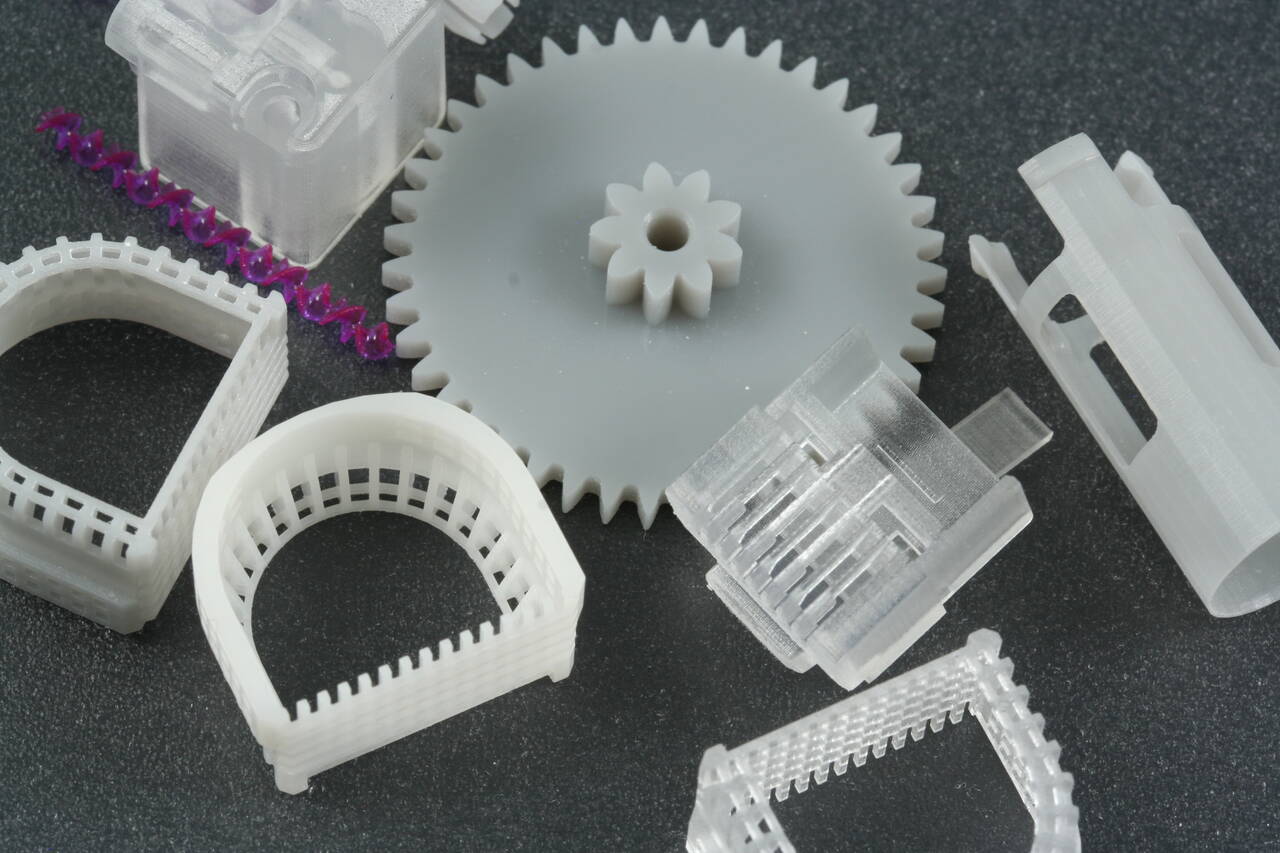

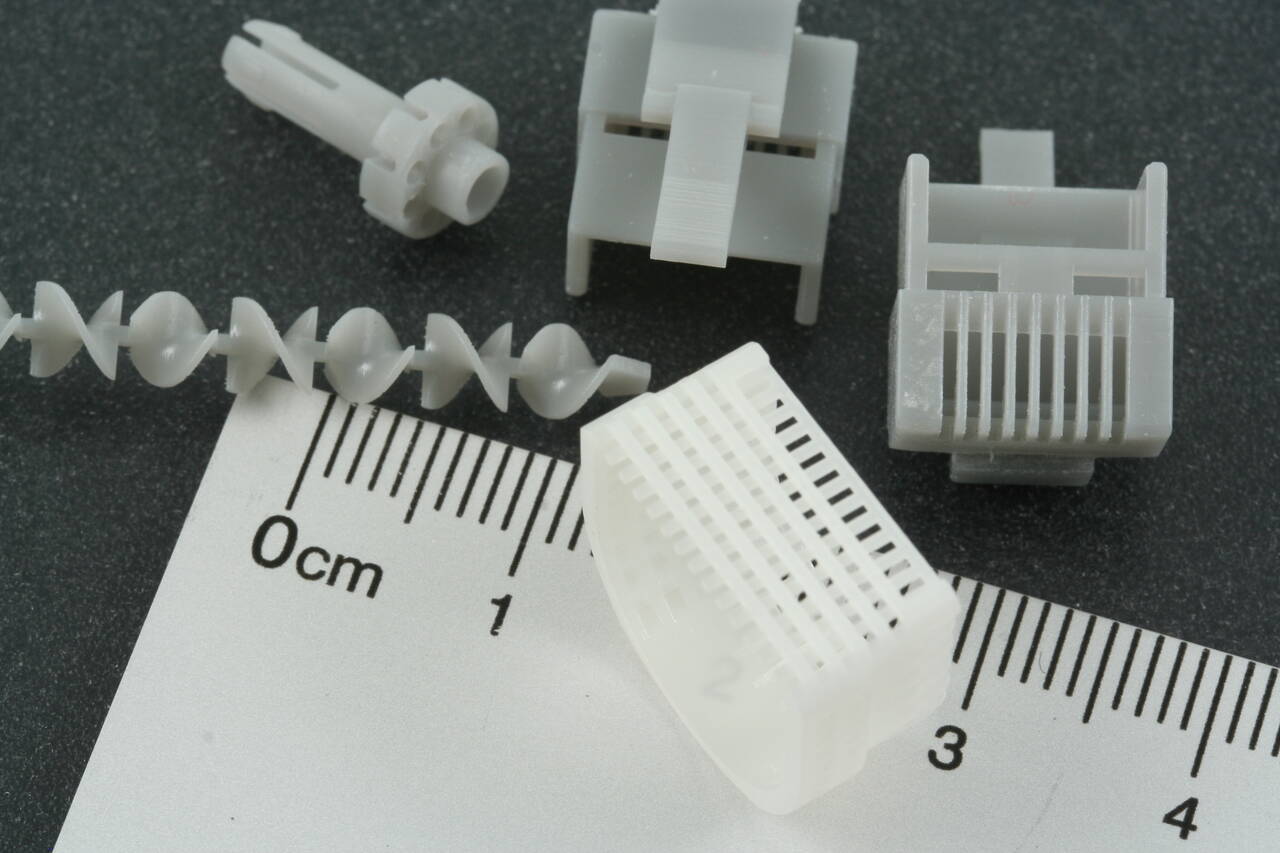

We are working with high resolution techniques for small feature parts.

The process

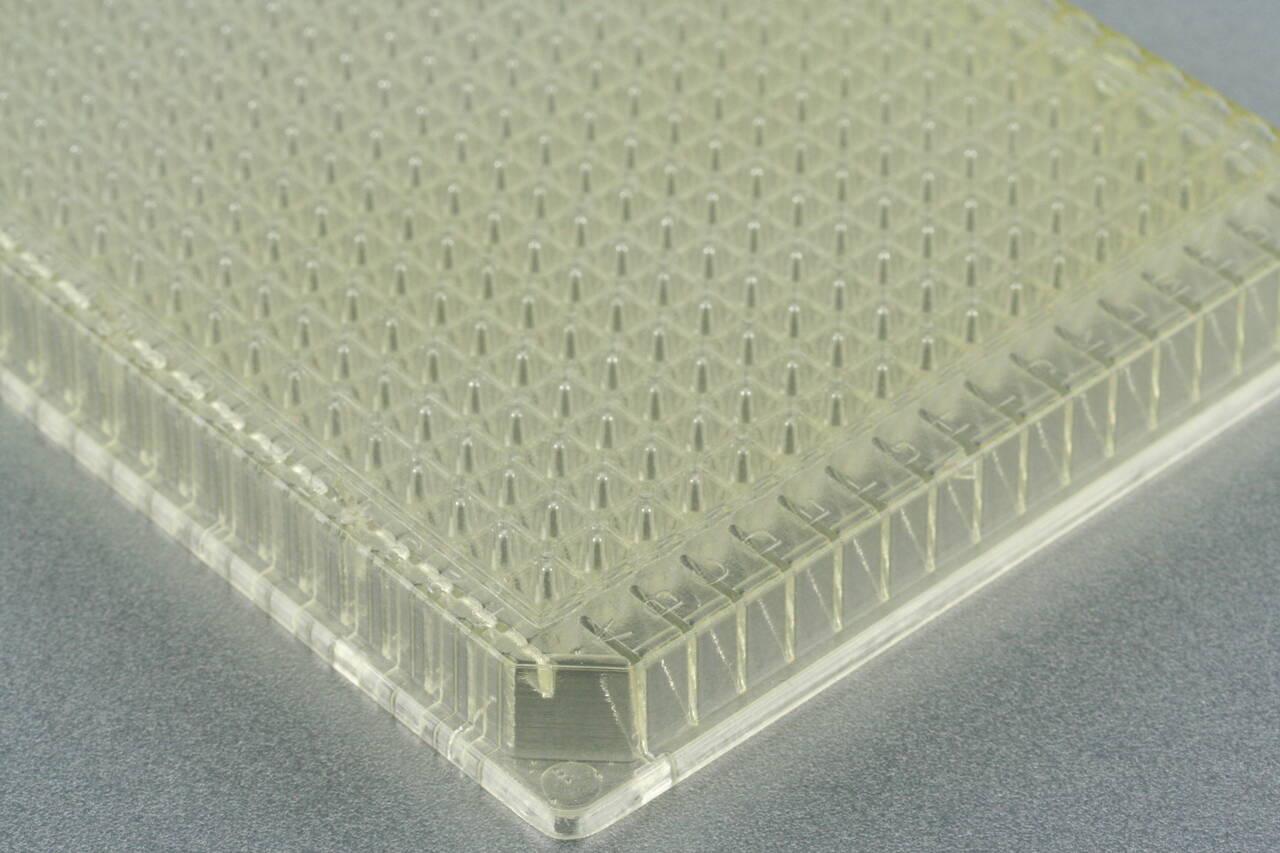

As a basis for the manufacturing, an STL file which digitally describes the prototype is needed. With special software, this object is sliced into a vast number of sections, each with a thickness of 0.05 - 0.25 mm.

A computer controlled laser beam "draws" those layers gradually onto the surface of a fluid photopolymer resin, whereby "drawing" means to initiate a local chemical reaction (polymerization). The polymerization depth fractionally exceeds the layer thickness in order to create a chemical bond between the respective layers. After each curing phase, the model is dipped into the resin by exactly one layer depth, whereupon it is freshly coated with liquid resin. The drawing of the next layer begins. After completion of the building process, the supports are removed. The model is once more cured with UV energy to fully harden. The model gets its final finish by hand.

Materials

To cover a large range of applications typically 10 of the most appropriate resins are constantly used at PROFORM. Some of them have been specifically optimized with respect to mechanical strength, flexibility, temperature or humidity resistance.

Special resins for high resolution or with USP Class VI, ISO10993 certification are available.

Our Resin Selector Guide helps you to find the right material(s) for your application!

For additional technical details regarding the materials PROFORM is using

have a look at our materials summary for stereolithography materials, DLP stereolithography materials

and BMF Micro 3D Printing materials.

Technical equipment

11 stereolithography machines in standard and high resolution with build envelopes

up to 380 x 380 x 400 mm³ (ProJet 7000, Viper si2, SLA-3500, Figure 4, BMF S240)

Delivery time

1 – 4 working days