Applications

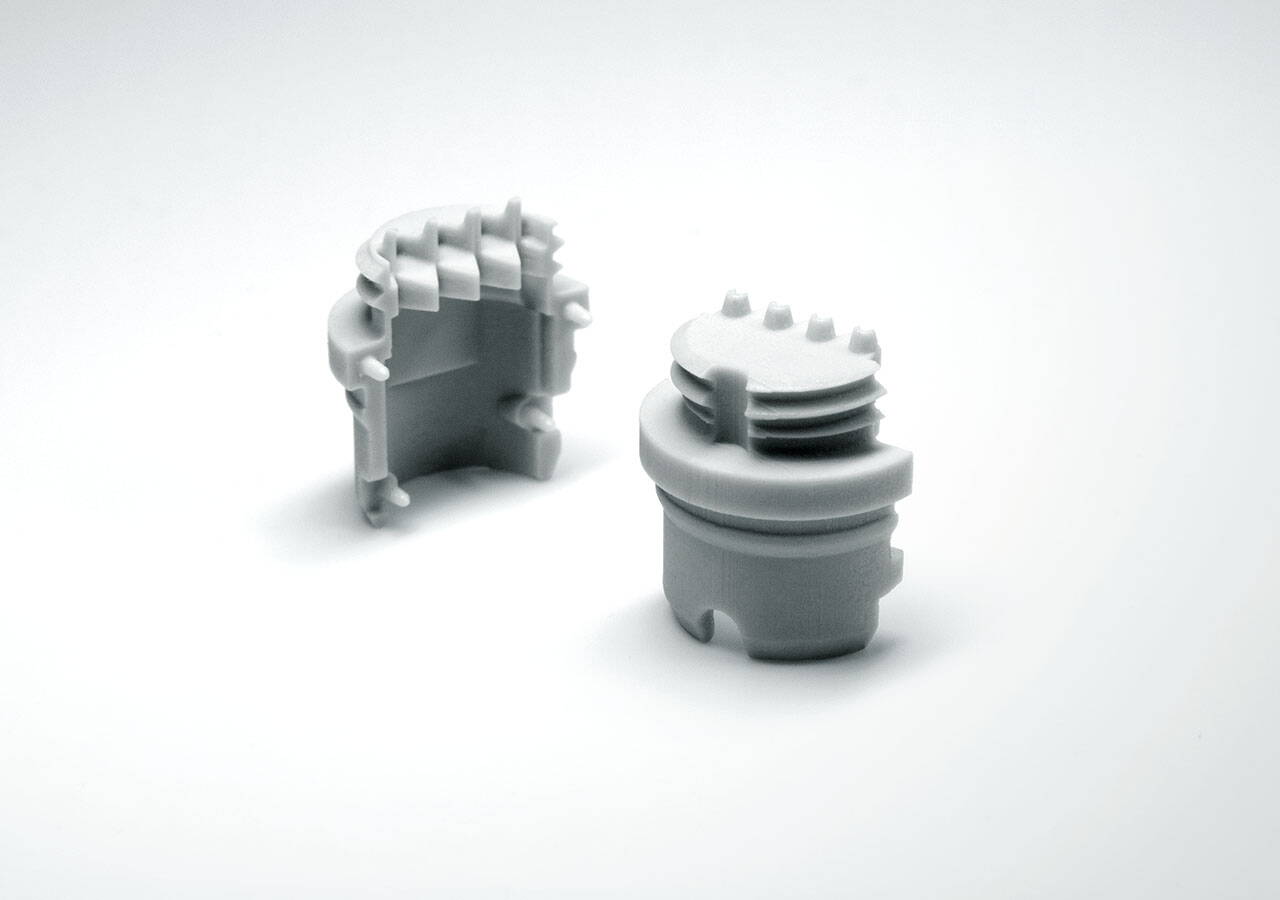

This method is used for relatively small and simple parts with a size of approximately 150 x 100 x 100 mm.

Typical is a series of 100 to 2000 pieces of smaller parts with no or few undercuts.

Rapid Tooling is also ideal for end product characteristics testing.

The process

Starting point is a precise stereolithography pattern of high surface quality. After defining the parting lines, this model is cast in two steps into a special metal-blended epoxy resin that cures to a metal-like material. Afterwards, the original model is removed and the rapid tool may the be surface finished as necessary.

The tool is then used for injection of common thermoplastic materials. The injection moulding is performed on a piston machine, whereby the parts are demoulded manually. The cycle time ranges typically from 1-5 minutes.

Materials

Thermoplastics e.g. ABS, PMMA, PE, PP, PA6, PA66, PC, etc.

Delivery time

2 - 4 weeks