TECHNOLOGIES

3D Printing

New: Micro 3D Printing

even smaller, more precise parts become possible with our new S240 from Boston Micro Fabrication

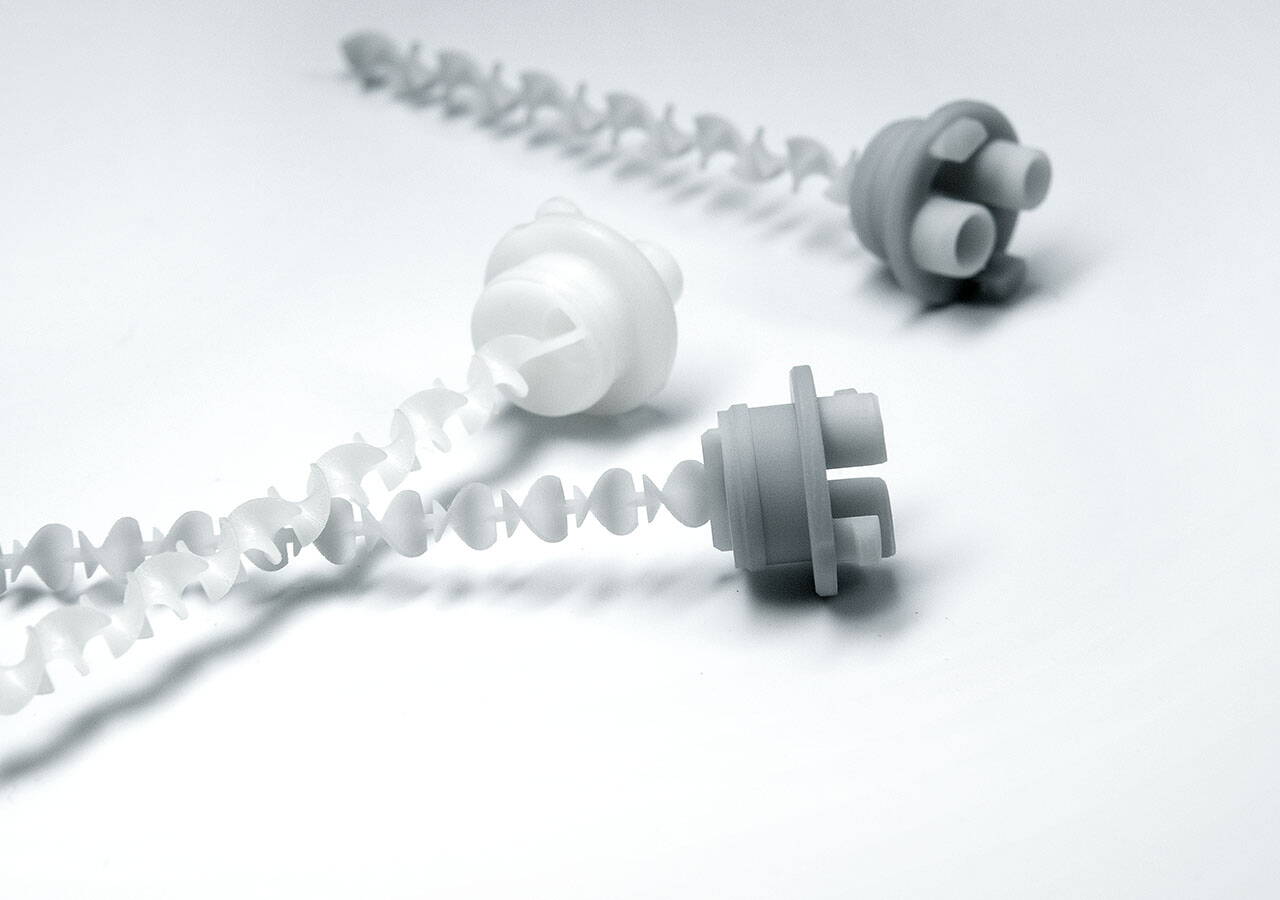

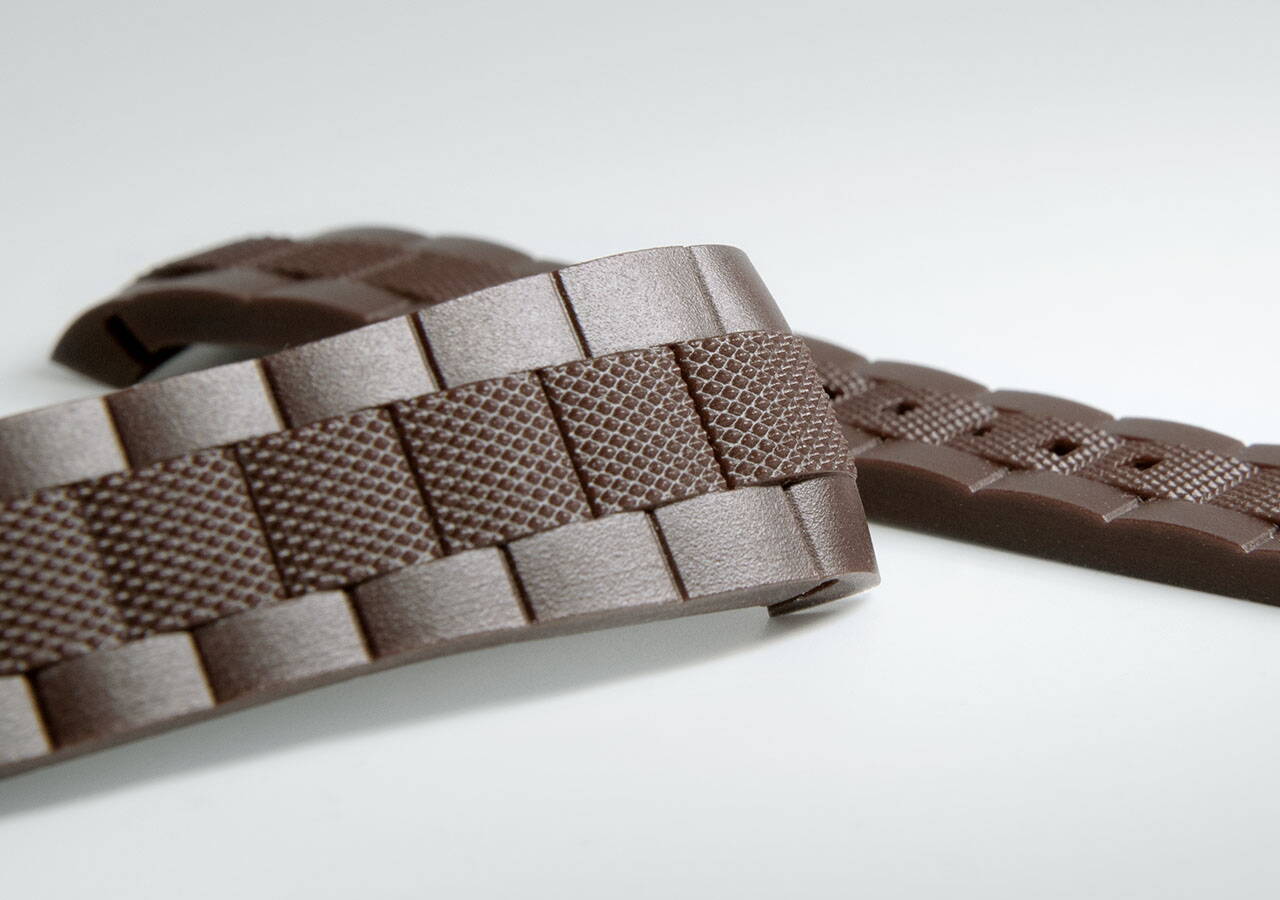

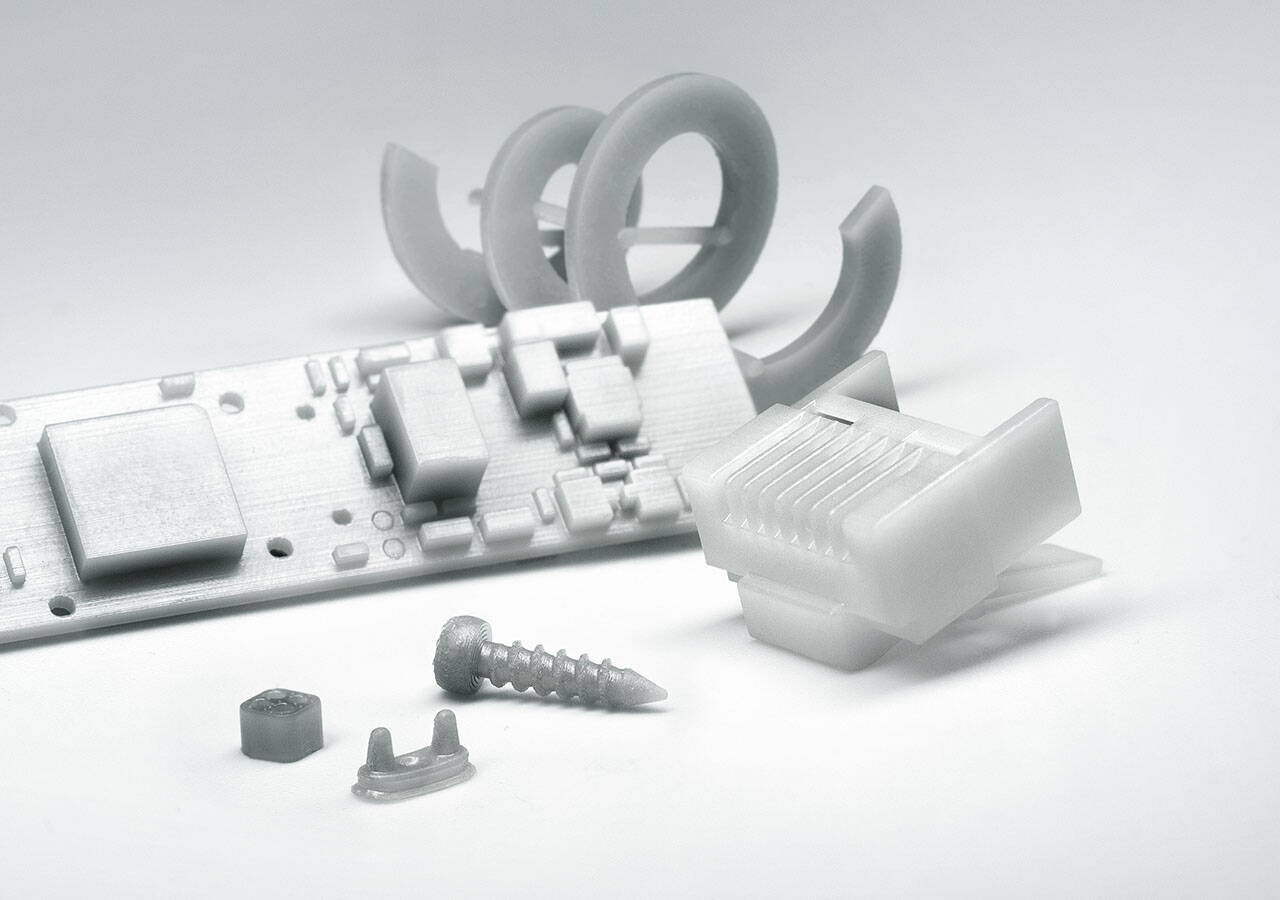

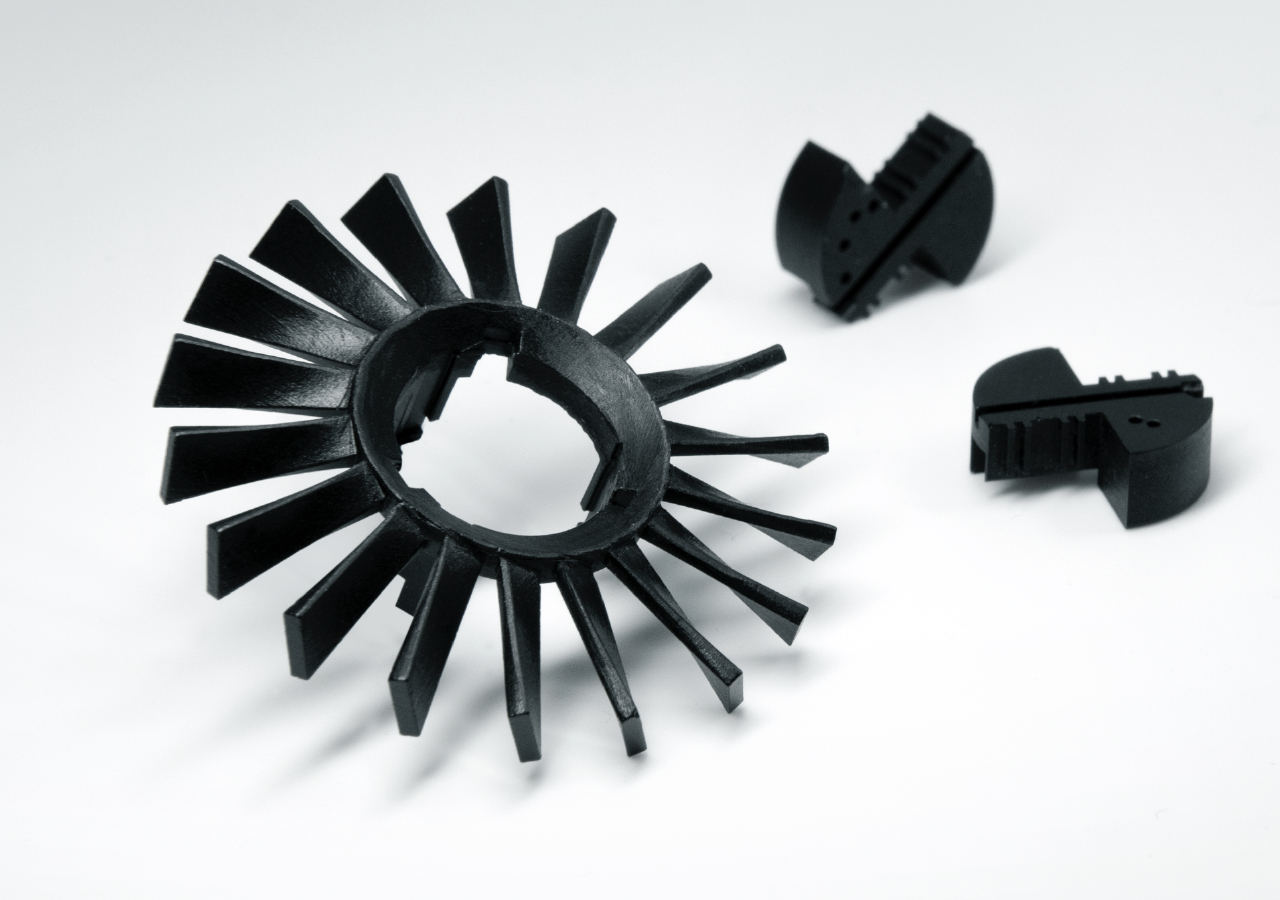

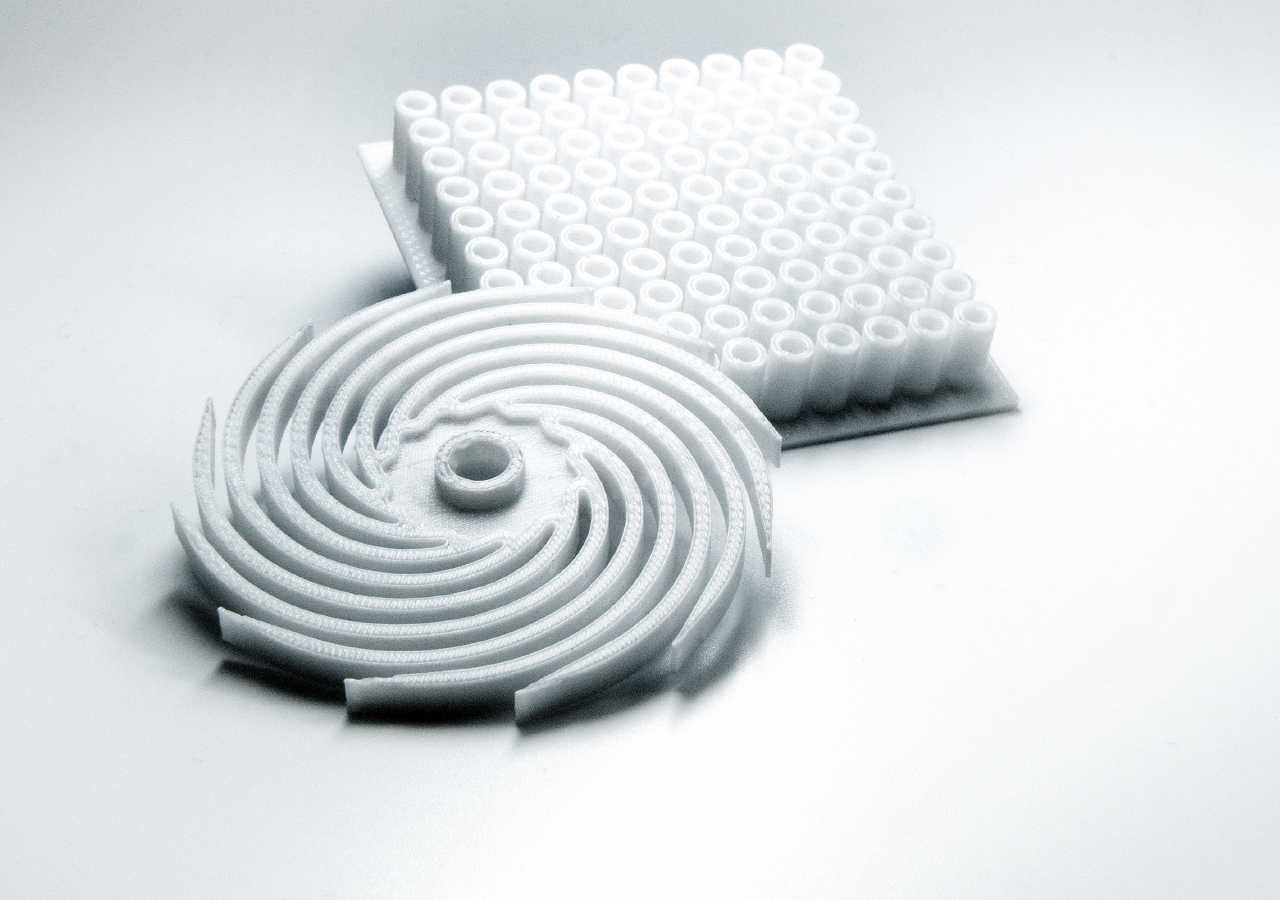

High quality 3D Printing /Additive Manufacturing

for parts of high complexity and with very small features in high resolution and best precision.

3D Printing / Additive Manufacturing in the most suitable materials.

Vacuum Casting

The method of choice for the quick and low cost production of small series of parts with specific material requirements (mechanical, thermal, visual,..)

Rapid Tooling

Larger series of small parts of moderate complexity can be produced by Rapid Tooling in production materials.

DATES AND Events

See you at

Swiss Plastics Expo

Messe Luzern, Lucerne

January 20 - 22, 2026

Booth: C 2075, hall 2

Get your free entry badge!

Click on the code below:

COMPANY

Provider of rapid prototyping services since 1991.

Thanks to our long-standing experience, our expertise and our powerful and flexible infrastructure we are an acknowledged specialist for the production of complex and very small parts in best quality.