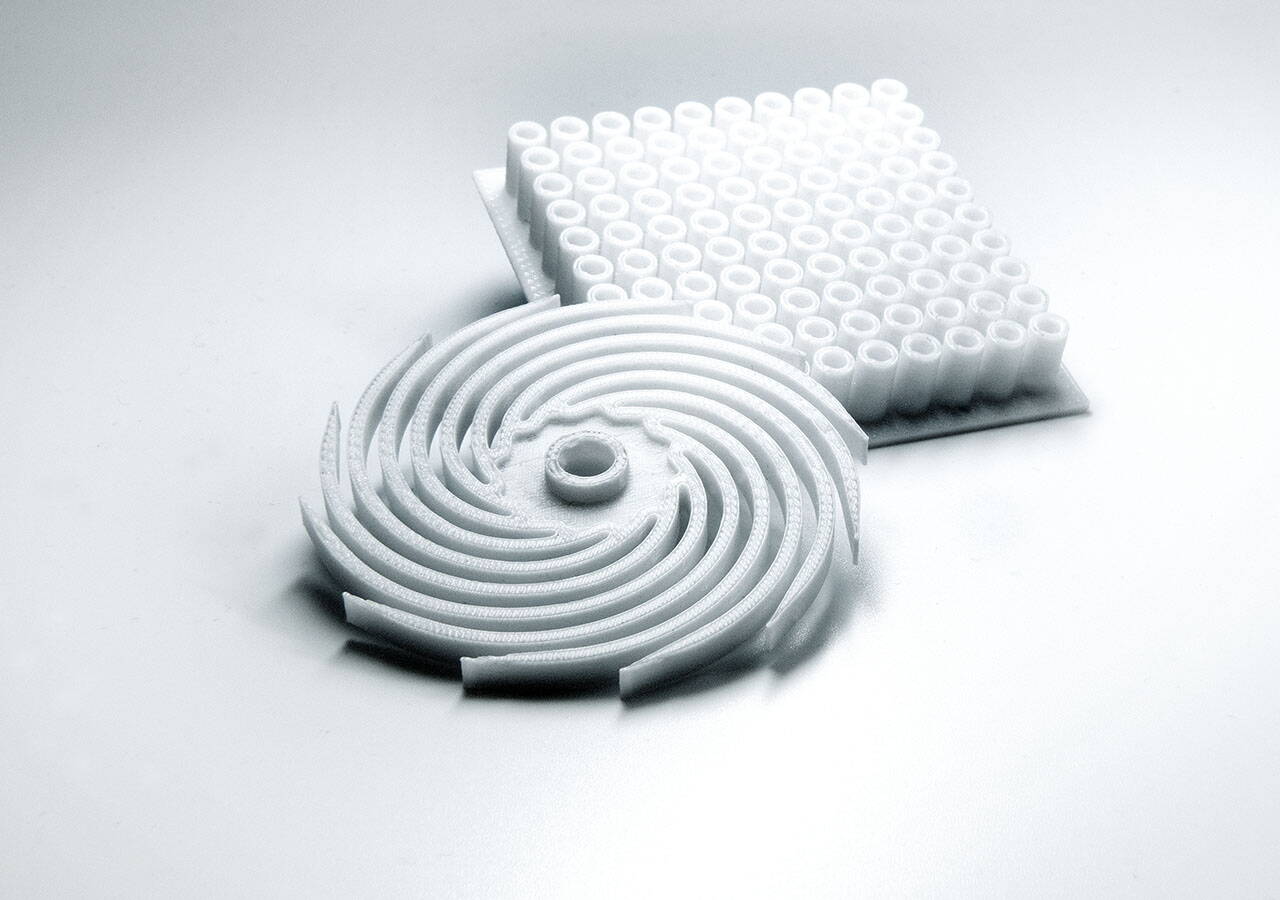

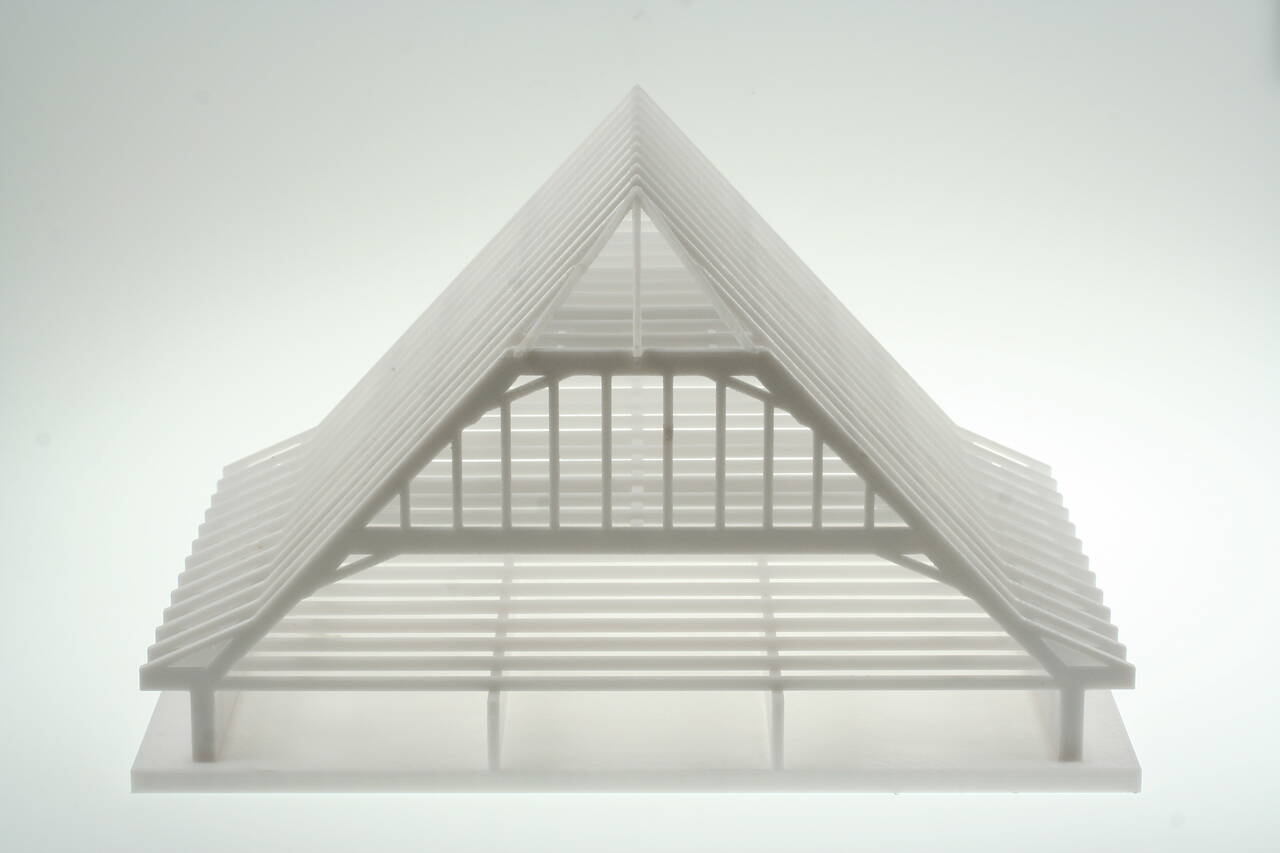

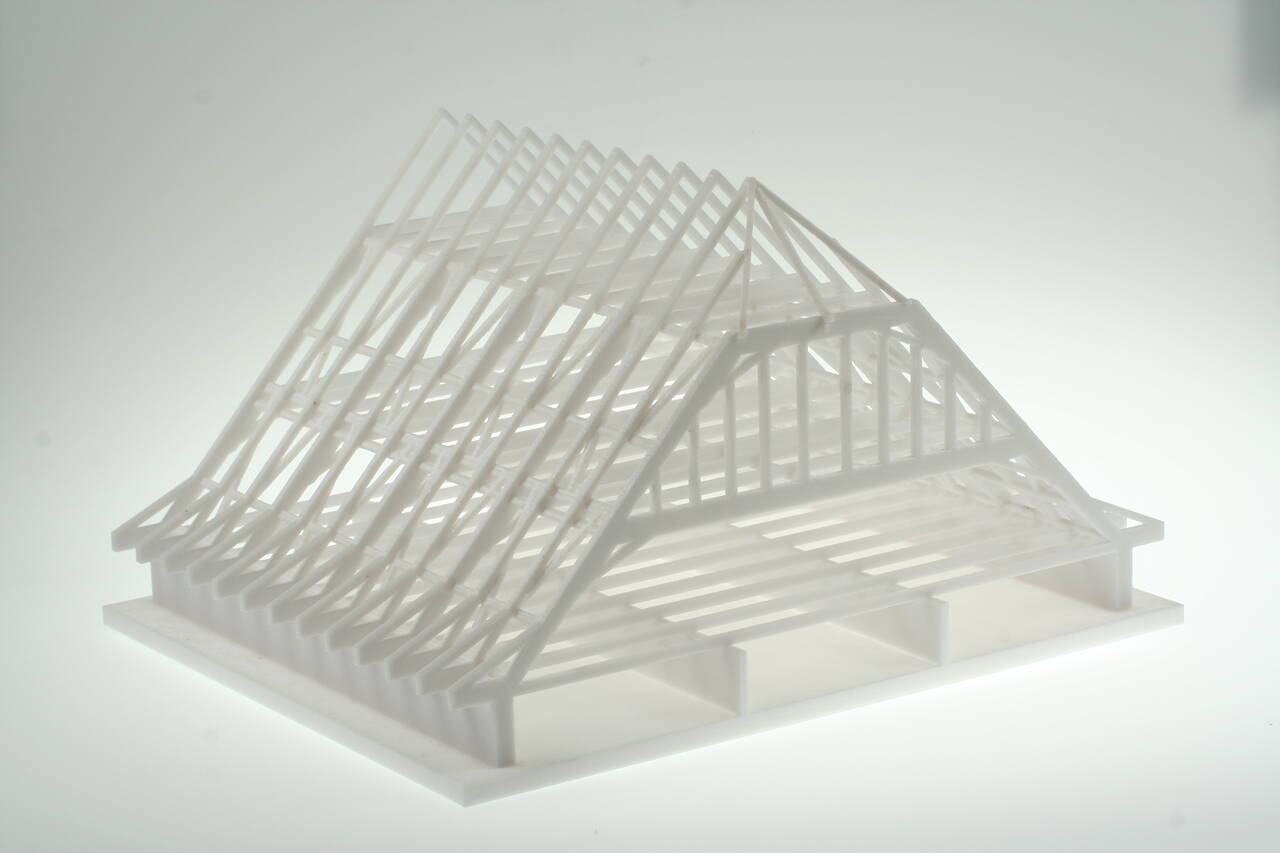

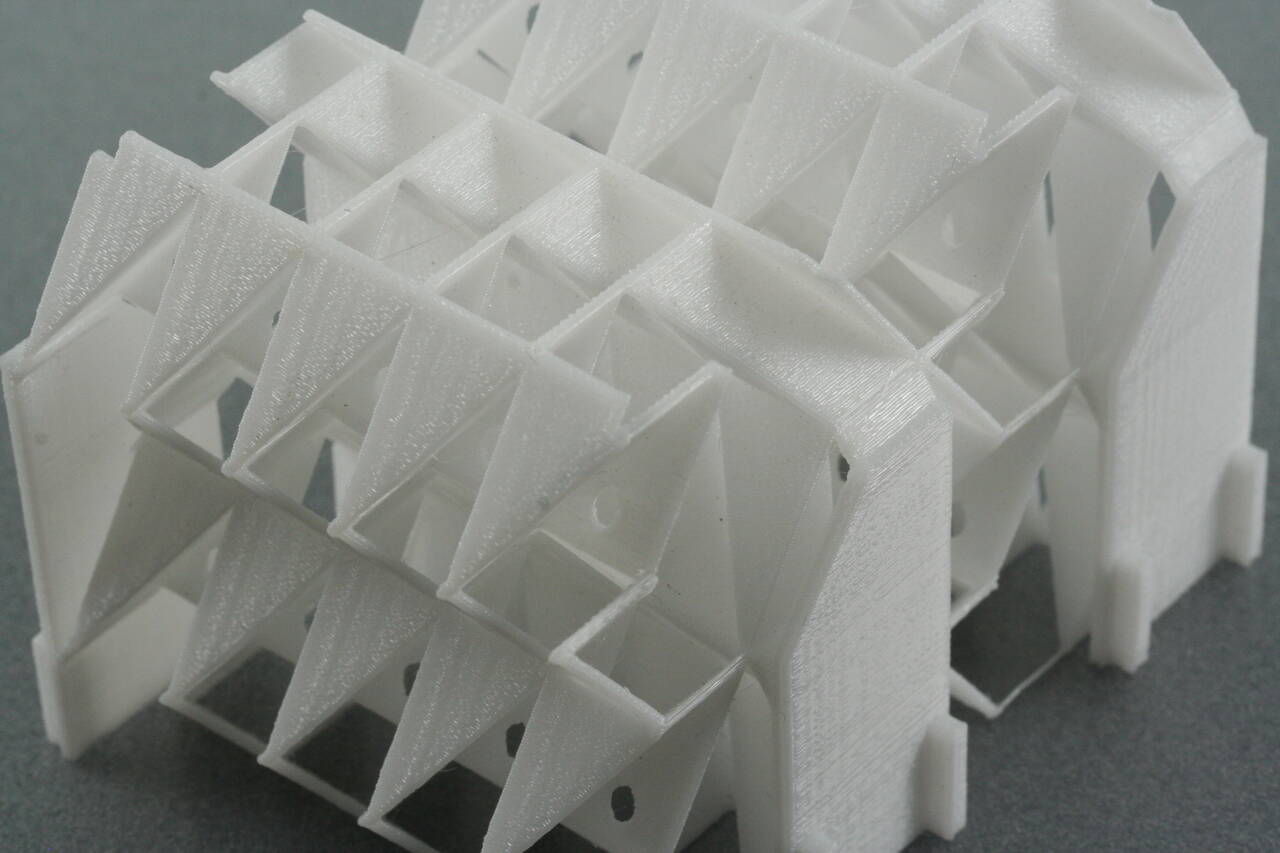

Applications

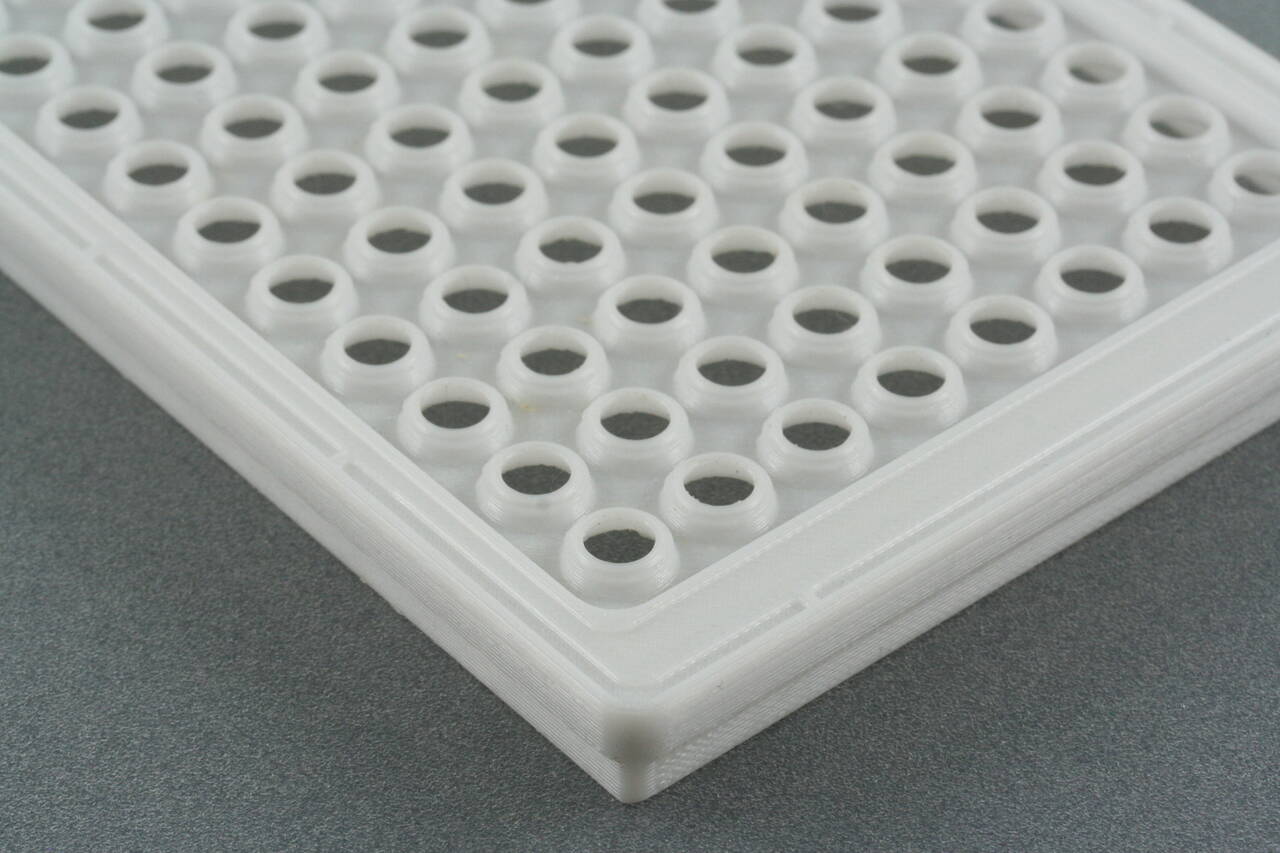

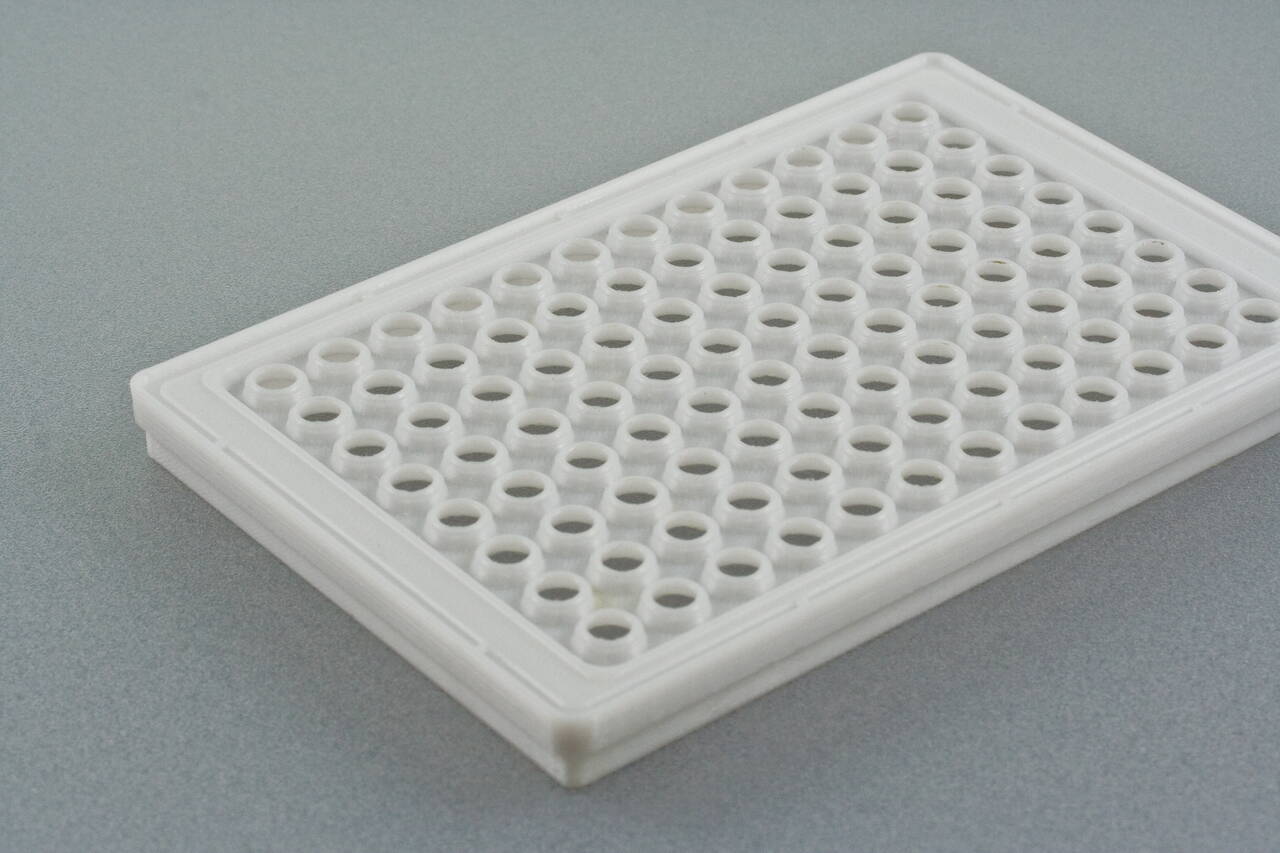

FDM models meet high demands regarding mechanical and thermal strength, impact resistance, chemical resistance and thermal deflection; ABS parts also serve as base models in the investment casting process.

The process

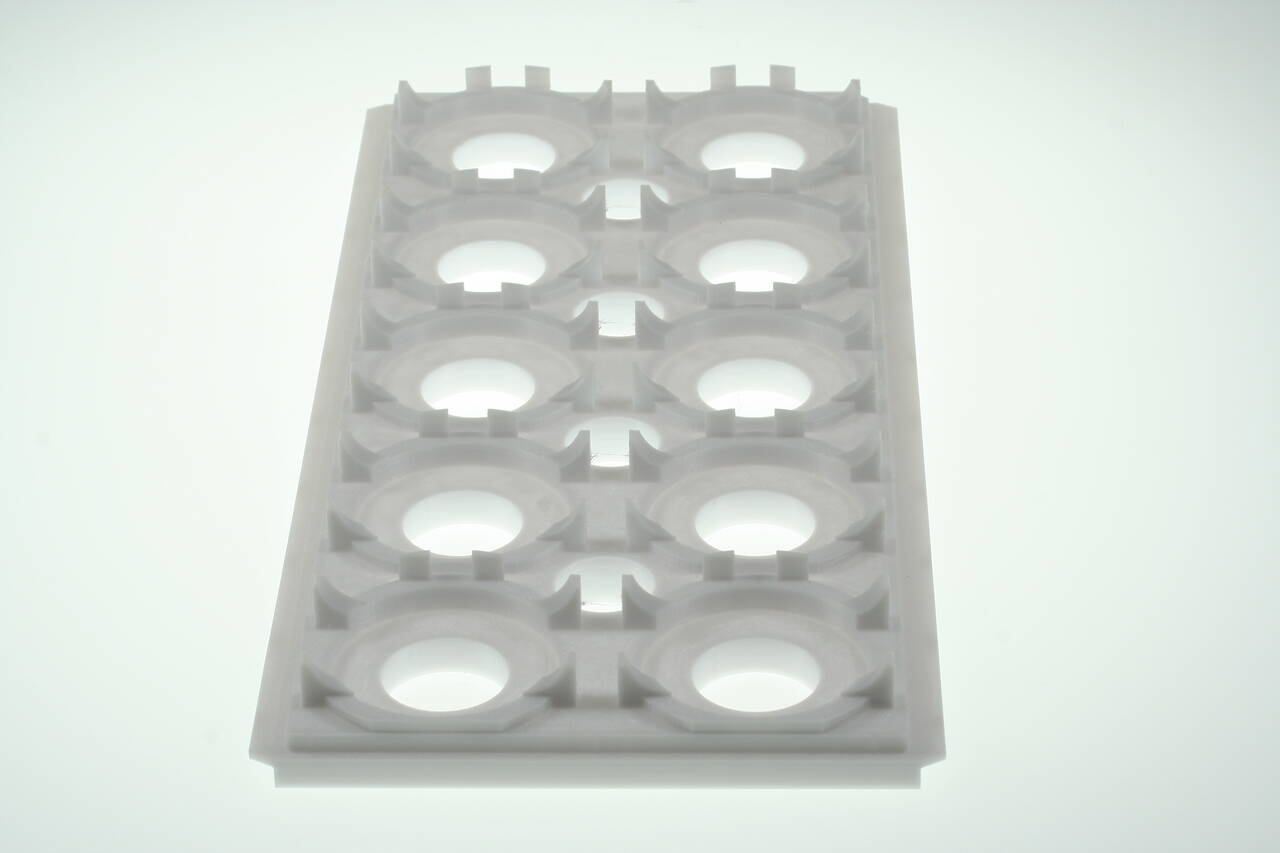

The FDM technology is an extrusion method. Comparable to stereolithography, the model is brought into position and sliced into very thin layers by means of special software. Mechanical support is generated for overhanging parts of the model. The parts are built by solidifying layer-by-layer a material that has been melted beforehand. The support is removed after the building process.

The material is provided in the form of coils and melted in a printing head, which extrudes it onto a building platform.

Materials

Polycarbonate (PC): for functional prototypes with a very high impact resistance and a thermal deflection of 125°C.

ABS: for functional prototypes with good mechanical strength and chemical resistance.

PC-ABS Blend (black): combines good mechanical and chemical resistance and can be processed with the water soluble support material (water works technology), particularly useful for complex parts.

Technical equipement

FORTUS 400mc Large - installation with maximal part dimensions of 408 x 355 x 408 mm³

Delivery time

1 - 4 working days